Home/TECHNOLOGY/aluminium foil packing process

aluminium foil packing process

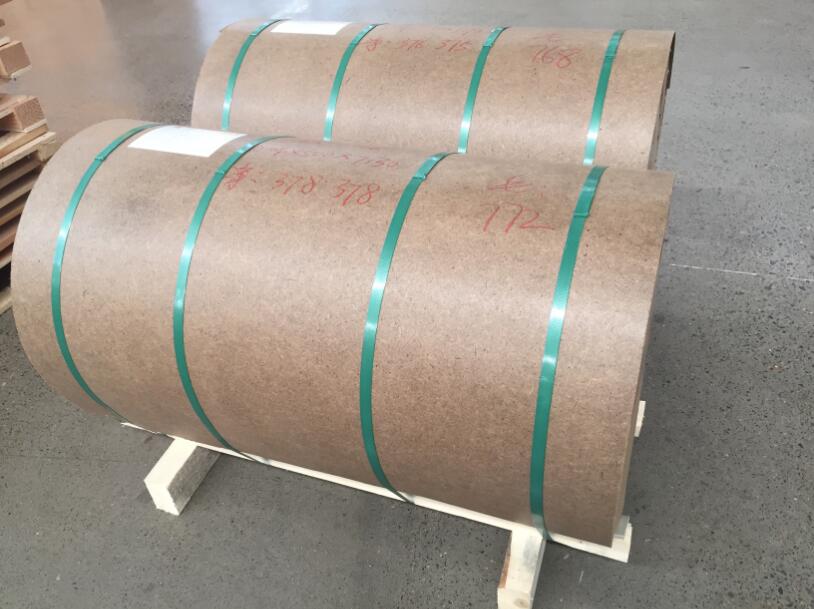

The packaging methods of aluminium foil can be divided into wooden box packing and wooden pallet packing/ well frame packaging according to their thickness and temper.

The wooden box packing is divided into stacking type, hanger bracket type and bottom bracket type. Stacking type is mainly used for small size and light weight products.

The bottom bracket type is mainly used for products with large specifications and large weight. hanger bracket type is mainly used for products of general specification and weight.

The packing of wooden pallet / well frame packagingis divided into eye to sky wooden pallet packing and eye to wall wooden pallet packing.

Recently our 7075 T651 and 6061 T651 have big promotion, please see price update as bleow

Recently our 7075 T651 and 6061 T651 have big promotion, please see price up...+ Details

Is Food Grade Aluminum Foil Toxic?

Aluminum foil is a metal substance and is not toxic. Chalco specializes in t...+ Details

Characteristics and application of coated aluminum foil

Coated aluminum foil is a relatively common material in social production. I...+ Details

Product Features of Medicinal PTP Aluminum Foil

Signi Aluminium is a medicinal aluminum foil manufacturer with excellent qua...+ Details

Medical aluminum foil quality requirements

The raw material used for the production of medical aluminum foil is pure al...+ Details