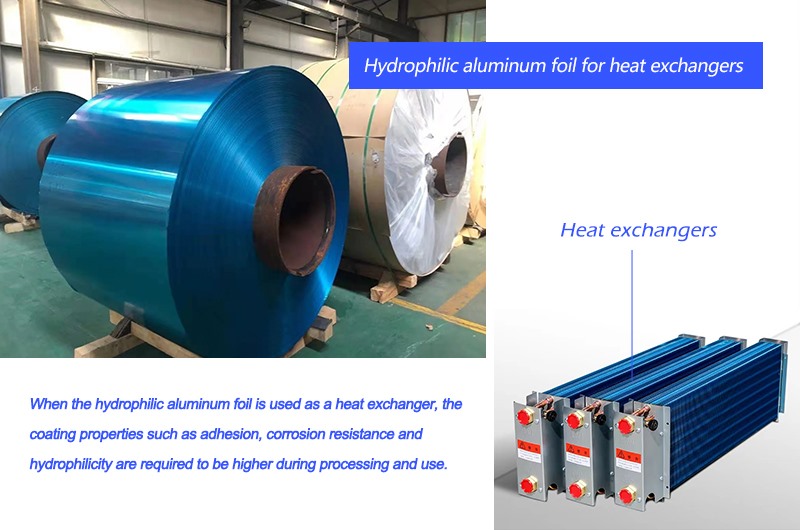

Hydrophilic aluminum foil, pretreatment process before hydrophilic aluminum foil coating:

When hydrophilic aluminum foil is used as a heat exchanger, its coating properties such as adhesion, corrosion resistance and hydrophilicity are required to be high during processing and use. In order to ensure the coating performance of hydrophilic aluminum foil, cleaning before coating Preprocessing is especially important. By means of neutral salt spray test, adhesion test and continuous hydrophilicity test, the formulation and optimization control of hydrophilic aluminum foil pretreatment process parameters are analyzed. Fraction), degreasing solution temperature 20~40℃, pH 10~13, hot water cleaning temperature 40~60℃, the cleanliness dyne value of the aluminum foil surface after treatment is ≥56, which can meet the production needs of hydrophilic aluminum foil.

Signi aluminium Hydrophilic aluminum foil for heat exchangers spec:

Alloy: 8006 , 8011 , 8079,3003, 3102,1060 ,1100,1200,1030B etc,

Temper:O, H22, H24, H26

Thickness: 0.08mm~0.25mm .

Width: 15mm~1250mm.

I.D: 75, 150, 200, 300, 400mm.

O.D: 400-1400mm

Surface:

Pretreatment process of Hydrophilic aluminum foil factory:

(1) During the pretreatment process before coating, the concentration of degreasing solution should be controlled at 2% to 5% (mass fraction), the temperature of degreasing solution should be controlled at 20-40 ℃, and the temperature of hot water cleaning should be controlled at 40-60 ℃.

(2) During the coating production process, the pH of the degreasing solution can be detected to maintain the effect of the degreasing solution, and the pH is controlled at 10-13. Before coating, the dyne value of the aluminum foil surface is clean and pretreated, and the dyne value is greater than or equal to 56, which can meet the requirements of coating production.

(3) The sigin process parameters of the pretreatment of the hydrophilic aluminum foil before coating are controlled, and the produced hydrophilic aluminum foil has a uniform surface, strong coating adhesion, good corrosion resistance, and good continuous hydrophilicity, which can meet the needs of different customers. Production demand of hydrophilic aluminum foil.

Recently our 7075 T651 and 6061 T651 have big promotion, please see price update as bleow

Recently our 7075 T651 and 6061 T651 have big promotion, please see price up...+ Details

Is Food Grade Aluminum Foil Toxic?

Aluminum foil is a metal substance and is not toxic. Chalco specializes in t...+ Details

Characteristics and application of coated aluminum foil

Coated aluminum foil is a relatively common material in social production. I...+ Details

Product Features of Medicinal PTP Aluminum Foil

Signi Aluminium is a medicinal aluminum foil manufacturer with excellent qua...+ Details

Medical aluminum foil quality requirements

The raw material used for the production of medical aluminum foil is pure al...+ Details